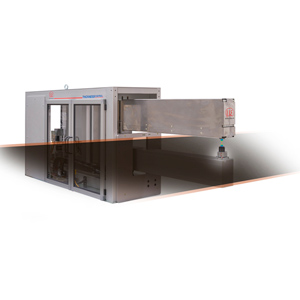

在全自动表面检测领域处于领先地位

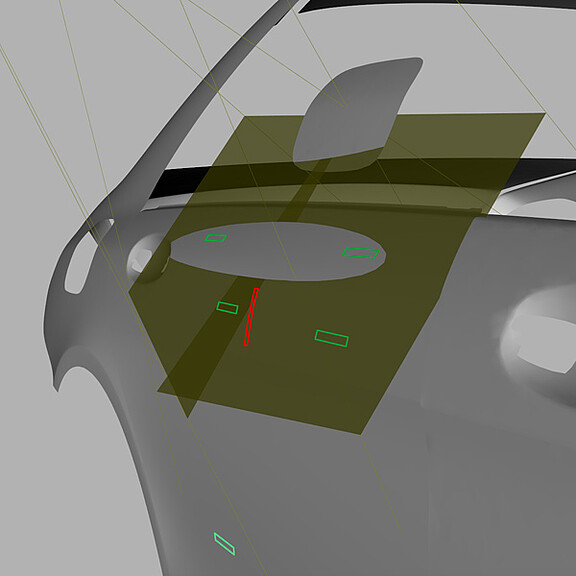

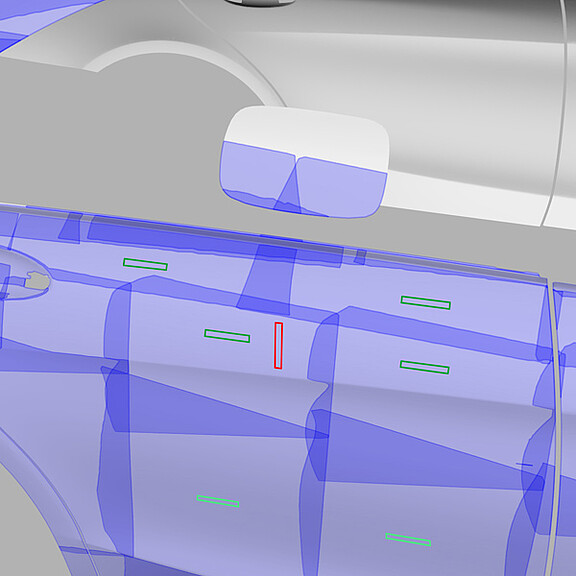

reflectCONTROL Automotive 能够实现车身漆面的全自动检测。这些机器人系统能够检测、三维测量并分类常见的漆面缺陷。

reflectCONTROL 系统具有高精度和可重复性,并且可以与自动处理和标记系统结合使用。这就是 reflectCONTROL Automotive 如何实现从漆面缺陷检测和评估,到自动后续处理的全自动化流程。

卓越的技术,无与伦比的检测率

采用 reflectCONTROL Automotive,汽车制造商能够实现超过 98.5% 的检测率——这一结果始终可复现,不受车身颜色及审计人员的影响。

由于缺陷的定位精度高,系统能够精确的检测和定位缺陷,从而实现后续的自动后处理,例如机器人打磨。

该检测系统实现了出色的区域覆盖率,能够检测到车身边缘 1 mm 范围内的缺陷。同时,它还能测量设计边缘,并具备足够的灵活性,可轻松适应车门、盖板等可移动部件的开合。

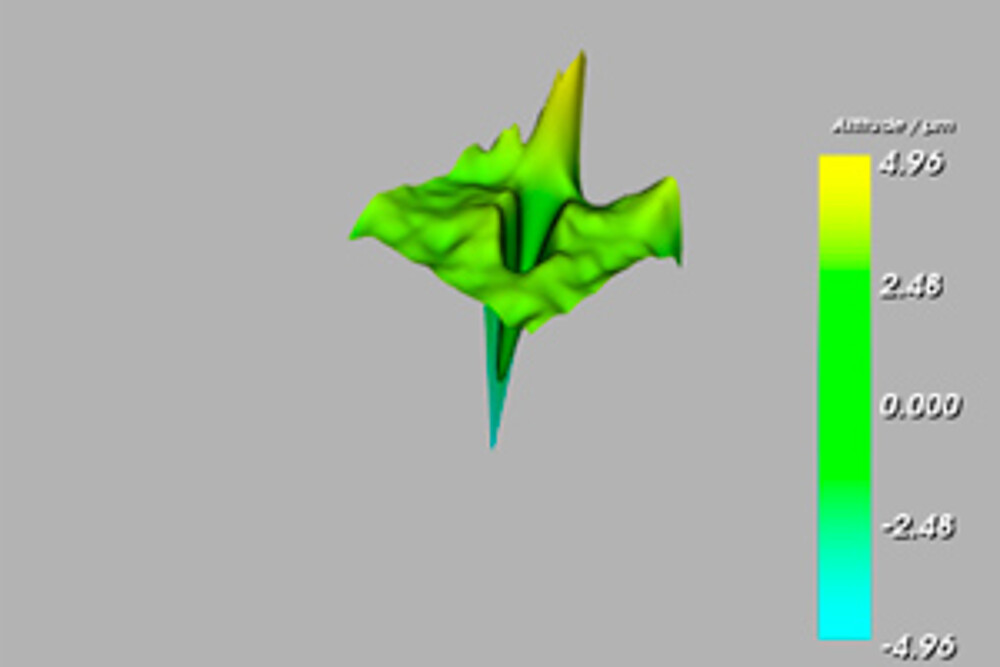

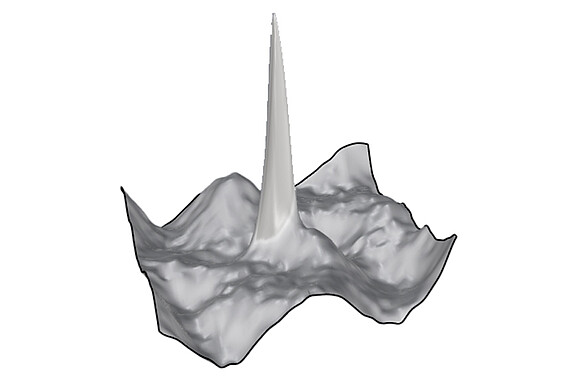

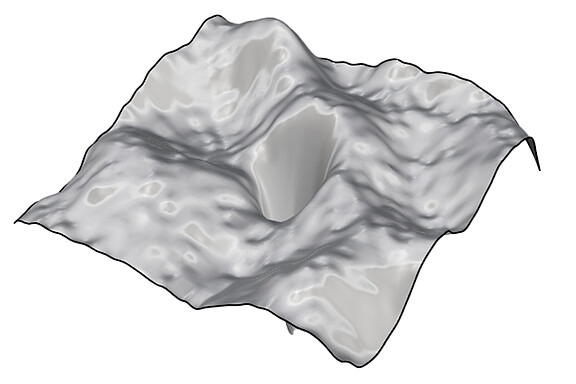

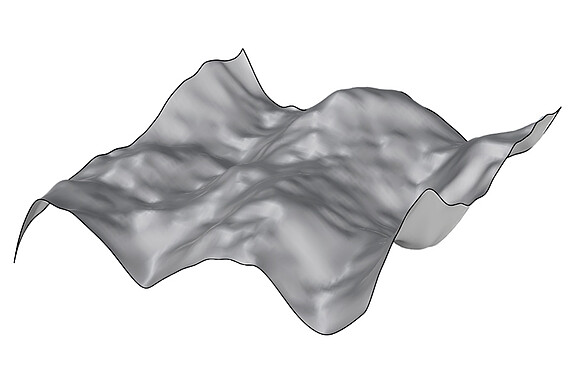

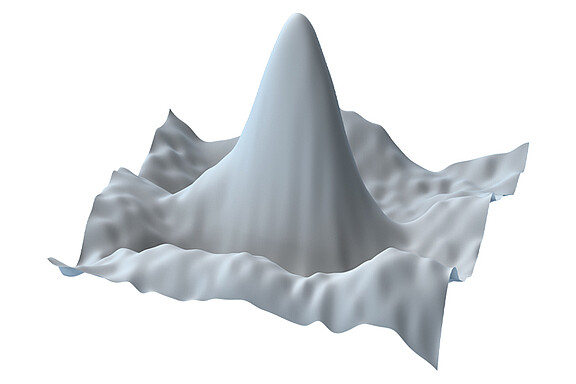

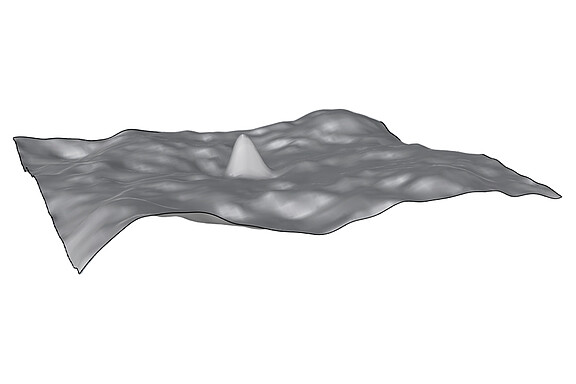

独特的 3D 重建功能能够为每个缺陷分配高度、深度和体积等特性。所获取的数据存储在 XML 文件中,用户可随时访问。此外,这些数据还可以读入用户的质量系统。

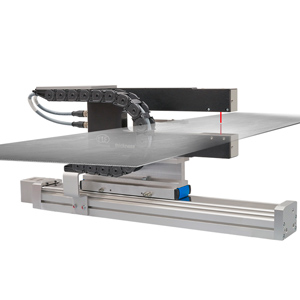

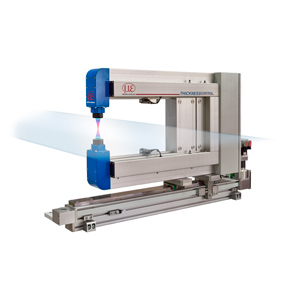

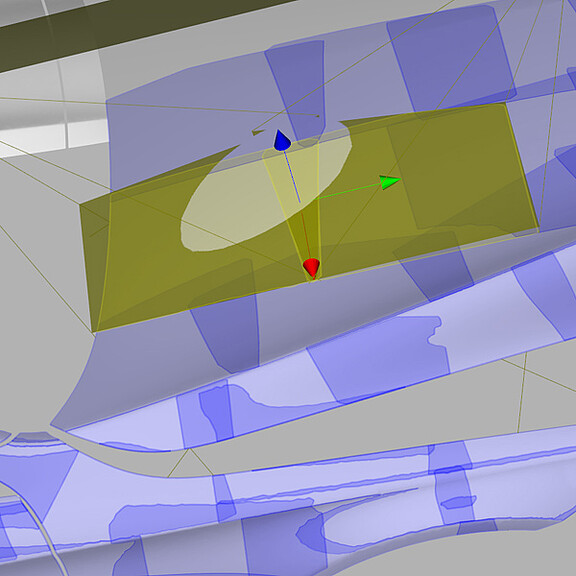

集成 6D 偏移校正

reflectCONTROL 检测系统具有一个集成的偏移校正功能,可以补偿位置公差。

系统能够全自动地计算出车身在检测站中的精确位置。因此,传感器的测量位置会进行相应地调整,从而实现快速、精确和高度可重复的测量。