当前位置:网站首页 > 技术应用 > 行业应用 > 机械加工/制造/自动化 >

油气管道内壁检测-2D/3D

------------------------------------------------------------------------------------------------------

发布日期:2015-01-27 浏览: 次

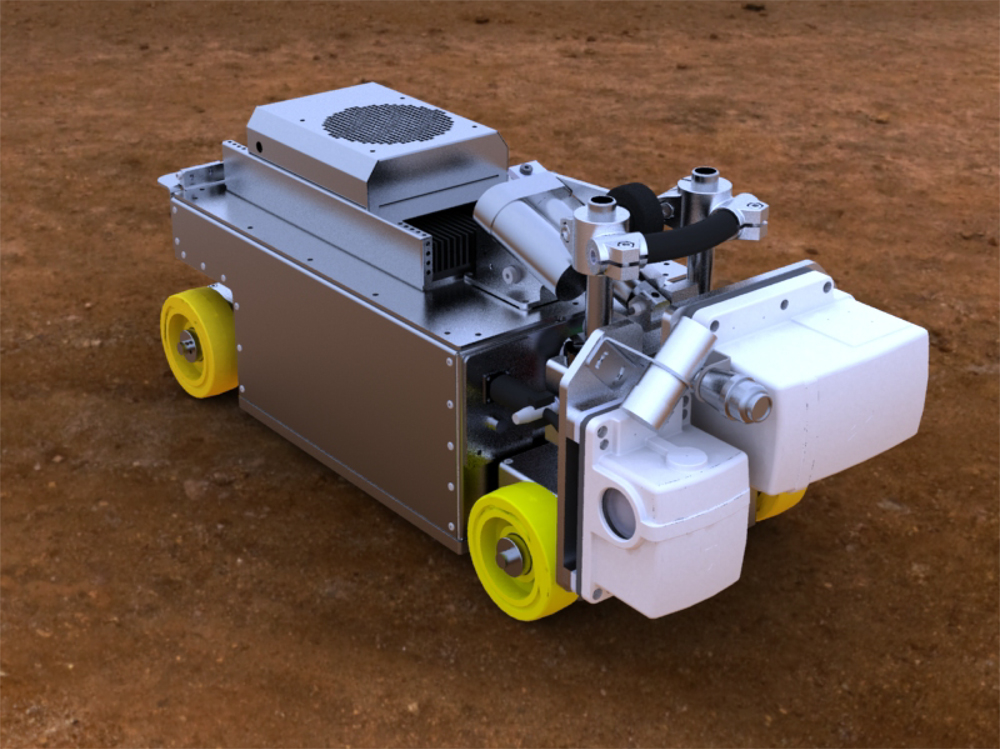

德国米铱公司激光轮廓仪被应用于油气传送管道远程检测车

出于安全因素考虑,用于传送油气的管道需要强制进行内部构造检测,以避免由于管道变形导致的爆炸,管道系统的崩溃,甚至重大人员伤害的发生。而管道内壁检测最重要的对象是焊缝结构,DEKRA公司采用德国米铱公司scanCONTROL激光轮廓仪,成功完成了管道焊缝的几何尺寸以及外观检测。

为了使检测车能够在全球不同地理环境下的使用,其被设计为可以防沙,防尘以及拥有100摄氏度的使用温度。小车配有五个轮子与管壁接触,可以上下45度的坡度。小车可以输出数据以备后续使用,或者根据需要,在发现诸如圆度,损伤和焊接问题时,随时触发报警信息.

ROV (Remotely Operated Vehicle) for pipeline inspection

To meet safety regulations, the inspection of the internal parts of pipelines is mandatory, as any deformations can lead to cracks, which could result in complete pipe failure or, in the worst case, to personal injury. The critical factor is the weld seam. DEKRA has developed a fully automatic vehicle that solves this task by using a combination of visual inspection and geometrical measurements performed by a scanCONTROL laser scanner from Micro-Epsilon.

To make the vehicle suitable for all types of pipeline in all regions of the world, it is protected against sand, dust and ambient temperatures up to 100 °C. In combination with the fifth wheel on the top of the vehicle pressed against the top of the pipeline, the ROV can travel up a high gradient of around +/- 45°. All data can be output for further use or, if desired, trigger an alarm as soon as an anomaly is found in the geometry (roundness, defects, welds, etc.).

版权所有:米铱(北京)测试技术有限公司 服务热线:010-64398534 京ICP备14053538号