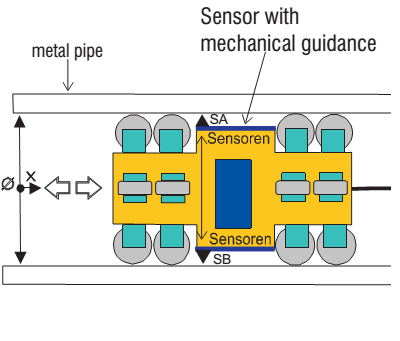

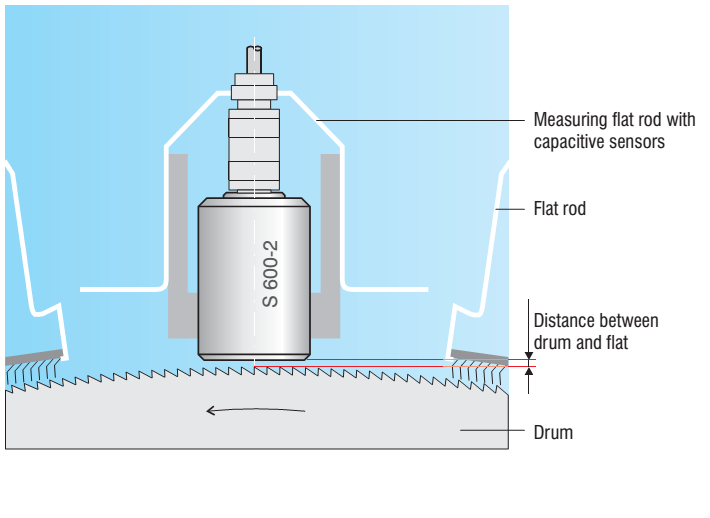

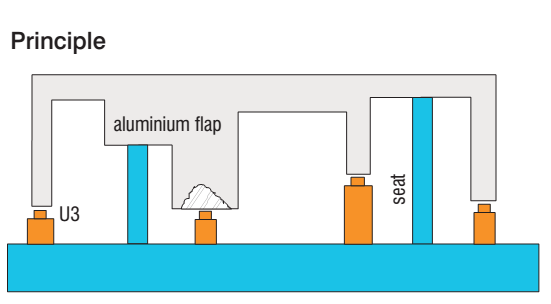

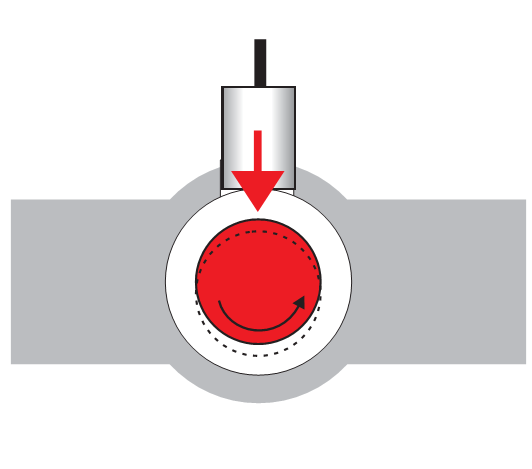

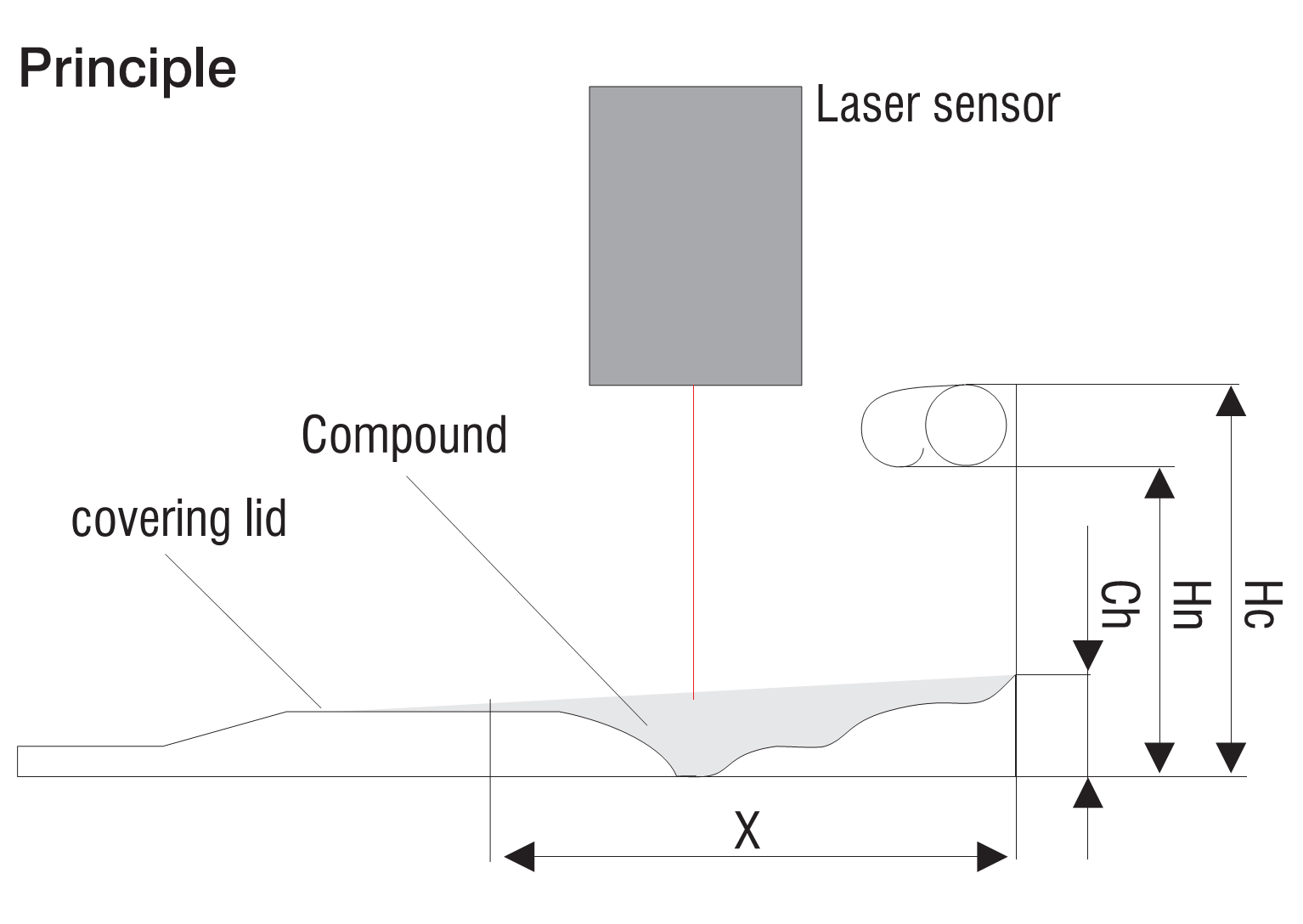

在诸如汽车催化器的应用当中,不锈钢管材的内径,最小外切和最大内切圆都必须得到精确控制。催化器中的套筒部位,可能是光洁表面,亚光面或带有涂层的表面,形状也可能是圆形或者椭圆形。尺寸精准对于将来催化器的工作至关重要。只需要准确安装被测物体,其他测量步骤都由计算机自主完成。In order to manufacture catalytic converters for cars, the diameter, minimum circumscribed circle, and maximum inscribed circle must be determined very precisely. The sleeve of the catalyst consists of either a gloss, matte or painted stainless steel tube, which can

[详细]