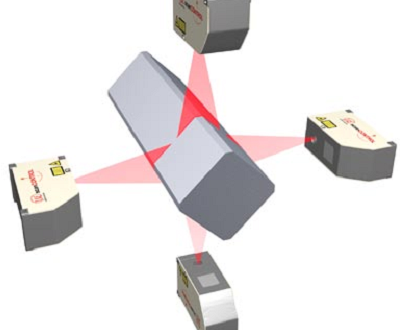

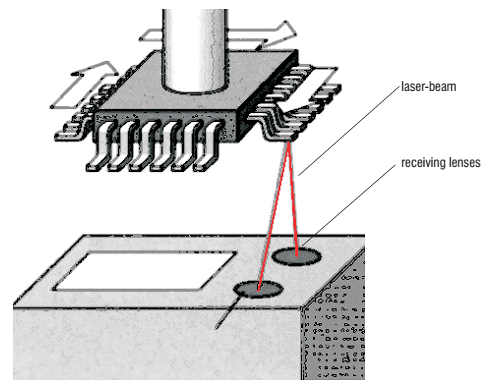

本案例用于测量多晶硅锭的众多属性,如边长,角度或者对角线长度。硅锭的表面光洁度也可以得到测量。采用激光轮廓扫描仪的好处很多,如非接触,免磨损以及对被测物体无机械影响。相对于人工检测,该系统稳定性非常高。The optical dimensionCONTROL 8260 for Ingots inspection system for silicon ingots automatically measures the surface of the ingot and automatically performs, among other things, a measurement of the side lengths, phase lengths, angles and diagonal lengths. The flatness of the side surfaces is also

[详细]